CATEGORIES

- Semi Trailer

- Leaf Spring

- Agricultural Trailer Drawbar Leaf Spring

- Toyota Leaf Spring

- Volvo Leaf Spring

- Hyundai Leaf Spring

- Man Leaf Spring

- KIA Leaf Spring

- Scania Leaf Spring

- Nissan Leaf Spring

- TRA Leaf Spring

- Hino Leaf Spring

- Isuzu Leaf Spring

- BPW Leaf Spring

- BENZ Leaf Spring

- Nissan Leaf Spring

- ROR Leaf Spring

- Mitsubishi Leaf Spring

- Trailer Leaf Spring

- Parabolic Leaf Springs

- Boat Trailer Leaf Spring

- Z Type Leaf Spring

- Mercedes Benz Leaf Spring

- Small Leaf Spring

- Coil Spring

- Trailer Spring in North America Picture

- Trailer Spring in North America Catalogue

- Semi Finished Leaf Spring

- ROCKER ROLLERS

- OFF ROAD SPRINGS

- EYE TO EYE SPRINGS

- SLIPPER SPRINGS

- Bolt

- Trailer Turntable

- Brake Drum & Hub

- Wheel Rim

- Landing Gear

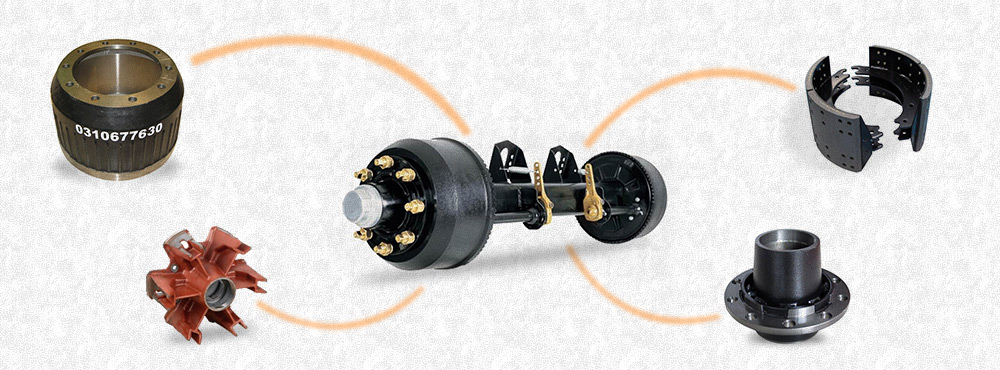

- Axle and parts

- Mechanical Suspension and parts

- Air Suspension

- Bogie

- Fifth Wheel & King pin

- Air Bag

- Slack adjuster

- Air chamber

- Twist Lock

- Mudguard

- Flat Bar

- LED Lamp

- Other parts

- Agricultural Machinery parts

- Trailer parts

CONTACT US

Tel:+86-592 5745970

Tel:+86-592 5745970 Mobile:+8618059238601

Mobile:+8618059238601 Whatsapp:+8618059238601

Whatsapp:+8618059238601 Wechat:+8618059238601

Wechat:+8618059238601 Email:market@wondee.com

Email:market@wondee.com

Why Leaf Springs Still Power Modern Trucks — Even in 2025

It’s 2025. Vehicles have autonomous features, electric drivetrains, and digital everything. And yet, tucked beneath the chassis of many trucks and SUVs is a suspension system that predates the steam engine — the leaf spring. Sounds ancient? That’s because it is. But just like the wheel, some old tech sticks around for good reason.

While most modern passenger cars have switched to coil springs for comfort and agility, leaf springs remain the suspension of choice in the commercial truck world. Why? Because when it comes to carrying heavy loads, leaf springs are still tough to beat.

If you’re wondering why this age-old solution is still thriving today, here’s what makes leaf springs so relevant — and why manufacturers and fleets continue to trust brands like Wondee for reliable, modern spring systems.

What Exactly Is a Leaf Spring?

A leaf spring is a long, curved strip (or stack) of steel that flexes to absorb the force of a bump. Instead of coiling vertically like modern springs, it runs horizontally along the axle. That horizontal layout spreads the load and impact evenly along the length of the spring, rather than focusing the pressure at a single point.

Most modern versions use multiple stacked layers — or "leaves" — that work together to absorb heavy impacts. This makes them incredibly durable under harsh conditions, whether you're hauling freight cross-country or traversing rugged terrain.

For high-strength applications, Wondee’s leaf springs offer engineered performance, combining traditional toughness with precision manufacturing.

Why Trucks Still Use Leaf Springs

So if coil springs are smoother and more comfortable, why don’t all vehicles use them?

Here’s the catch: coil springs can’t handle extreme weight. They're designed for flexibility and comfort, not raw load-bearing strength. When subjected to the stress of constant heavy cargo, they risk deformation or even breakage.

Leaf springs, on the other hand, excel in:

Load capacity – They’re built to carry massive weight without failure.

Durability – Ideal for rough roads, construction sites, and long hauls.

Simplicity & cost – They're less complex, easier to maintain, and more affordable to replace.

This is why many trucks use coil springs up front for driver comfort, but rely on leaf springs in the rear — right where the heavy lifting happens.

For fleet operators, choosing Wondee leaf springs means investing in affordable performance with long-term reliability.

Coil Springs: Smooth but Specialized

There’s no doubt that coil springs have taken over in the world of cars. They’re tightly wound coils that absorb bumps efficiently and provide a smooth ride. Because they act instantly without the internal friction of stacked metal leaves, they’re ideal for:

Passenger vehicles

Light-duty SUVs

Sports cars and performance applications

But their main weakness is in vertical load concentration. In a coil spring, all the force is focused into a small area. That makes them great for comfort — but not ideal for a fully loaded truck bed.

That’s why leaf springs remain essential in the commercial and off-road world, where payload capacity and toughness matter more than ride softness.

The Bottom Line: Leaf Springs Aren’t Obsolete — They’re Just Specialized

Yes, leaf springs are old tech. But like the wheel, they’ve earned their place by doing something very well — and very affordably. For fleets, heavy-duty drivers, and off-road adventurers, leaf springs are still the smart choice.

And if you’re looking for reliable, high-performance suspension components, explore Wondee’s full range of leaf springs — designed for today’s trucks, made with tomorrow in mind.