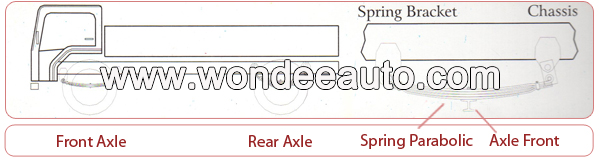

A parabolic spring is basically a leaf or a set of leaves which are tapered in a parabolic way rather than a linear.So from the middle,where leaf is thick,to the ends,where it is thinner,the tapering steps down in a parabolic manner.The tapering in a single leaf handles the force distribution from the vehicle to the axle and works better than conventional spring.The leaf spring is a vital link between the chassis and the axle of the vehicle.It has the additional role of absorbing and storing energy,and releasing it.It has a uniform stress prttern throughtout its length.As to efficiency,it is quite a few leaps ahead of the conventional leaf spring.

1.Parabolic spring assembly contains less number of leaves as compared to Conventioal spring assembly but can carry equal load.

2.Parabolic springs are suited for long drives,provide better ride comfort and control to the driver.

3.Each leaf of parabolic assembly acts as a separate spring.

4.In parabolic spring assembly all leaves are of full length carrying equal load as in conventional leaf spring assembly.

5.There is a gap between parabolic leaves, which reduces the friction between the leaves and provides better ride comfort.

6.The weight of parabolic assembly is lesser by 30% than the conventional spring assembly, in turn the pay load of the vehicle increases.

7.In parabolic spring the eye thickness is increased as compared to conventional spring, which reduces the eye failures in the field.

8.Raw material grade used for manufacturing parabolic spring is 50CrV4/SUP 11A which has higher strength as compared to 65Si7/SUP 9A used in conventional spring.

9.Centre lines are used in parabolic assembly to avoid friction, water and mud blockage between the leaves which is not the case in conventional assembly.

10.In order to improve fatigue life, parabolic springs are stress shot peened in controlled manner in comparison to conventional springs which are shot peened.

11.Henkel coating for better surface protection is done in parabolic springs compared to black oxide coat in conventional springs.

12.Load carrying capacity in case of parabolic spring assembly with addition of one parabolic aux leaf is leaf is equal to the addition of three leaves of conventional springs.