Heavy-Duty Trailer Turntables for Agricultural & Commercial Vehicles

- 1st China’s company to R&D for overseas market in 1999

- 20+ years production experience (since 1999)

- Implementing IATF16949-2016

- Implementing ISO9001-2015

- Radial clearance: ≦ 0.65 mm (European Standard 0.70 mm)

- Axial clearance: ≦ 0.90 mm (European Standard 1.00 mm)

- Technical standards: JT/T651-2006 & LY/T1292-1998

- Warranty: 24 months since shipping date

- Sales volume (units): 20,000+ per year

- Customer satisfaction: 100%

- Dispatch within Customized Production Based on Your Requirements : Your order will be manufactured according to your specifications (size, material, usage, etc.) with professional engineering support..

- Lead Time: 3–60 Days Depending on Quantity and Specification Warranty: Production and delivery time may vary based on your order volume and customization details. Contact us for an accurate schedule.

Description

A trailer ball bearing turntable plays a vital role in linking tractors, trailers, or trucks, allowing smooth turning while effectively transferring towing forces. Our turntables find extensive applications across heavy-duty full trailers, light truck trailers, agricultural trailers, and various specialized vehicles and industrial equipment. Since 1999, WONDEE Autoparts has been pioneering in this field by introducing China’s first trailer turntable designed specifically for the international market.

Product Highlights and Technical Details

Crafted to automotive-grade standards, our turntables deliver reliable performance backed by rigorous quality control.

- Quality Management: We adhere to the IATF16949:2016 automotive quality system and ISO9001:2015 standards.

- Compliance: All products meet or exceed JT/T651-2006 and LY/T1292-1998 technical requirements.

- Materials: Manufactured using QT500-7 ductile cast iron, ensuring tensile strength above 500 MPa for enhanced durability.

- Clearances: Radial clearance is controlled within ≤ 0.65 mm, tighter than the European benchmark of 0.70 mm; axial clearance is ≤ 0.90 mm, also better than the European standard of 1.00 mm.

- Precision: Dimensional deviations in height and diameter remain within ±0.5 mm, far surpassing the European tolerance of ±3.0 mm.

- Surface Quality: Ball rail surface roughness measures Ra 0.8 μm, with overall surface roughness at Ra 3.2 μm; flatness is maintained at ≤ 0.15 mm.

- Dust Protection: Equipped with a dual-stage dust-proof design to ensure long-lasting operation under harsh conditions.

Comprehensive Turntable Information

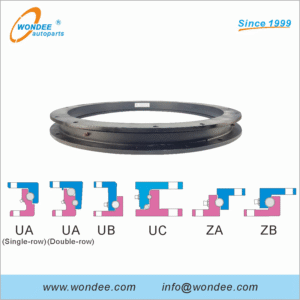

WONDEE offers a variety of turntable series to meet your needs.

| Series | UA type, UB type, U type, ZA type, ZB type, UC type |

| Axial Capacity | 2 Ton ~ 22 Ton |

| Size/Diameter | 300 mm ~ 1200 mm |

| Height | 45 mm ~ 94 mm |

| Bearing Ball Race | Single-row ball race, double-row ball race |

| Mounting Hole | Drilled or undrilled |

| Standards | IATF16949, ISO9001-2015, JT/T651-2006 & LY/T1292-1998 |

Turntable Models and Replacements

We provide a wide selection of turntables, including models that serve as replacements for major brands like JOST, Buer, and BPW.

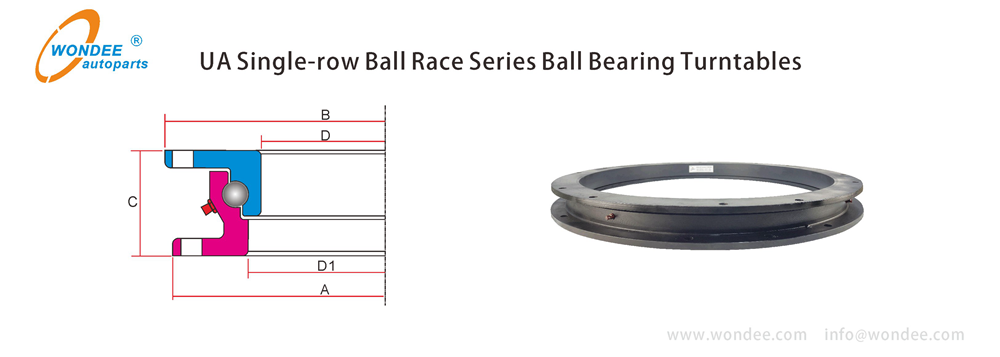

UA Type Turntables with Single-Row Ball Race

| Item No. | ØA (mm) | C (mm) | Tonnage (ton) | Replacement |

| TS1000-92UA01 | 1000 | 92 | 10 | KLK SO 1000-24 |

| TS1000-90UA01 | 1000 | 90 | 10 | KLK HE 1000-22 |

| TS1090-80UA01 | 1090 | 80 | 6.5 | KLK HE 6 |

| TS880-80UA01 | 880 | 80 | 5 | KLK HE 5 |

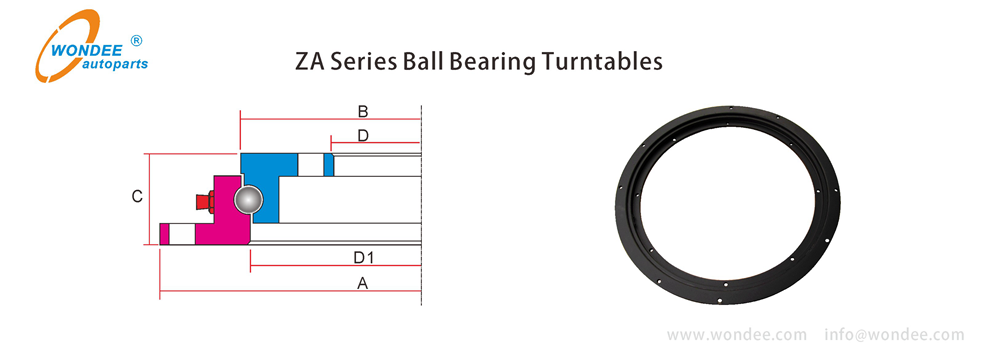

ZA Type Turntables

| Item No. | ØA (mm) | C (mm) | Tonnage (ton) | Replacement |

| TS1050-56ZA01 | 1050 | 56 | 5 | KDL 900-6 W |

| TS750-56ZA01 | 750 | 56 | 3 | KDL 900-3 W |

| TS520-56ZA01 | 520 | 56 | 2 | KDL 900-1 W |

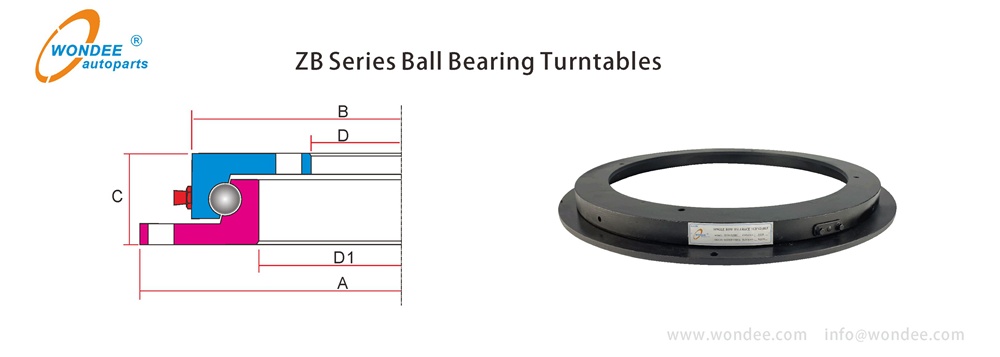

ZB Type Turntables

| Item No. | ØA (mm) | C (mm) | Tonnage (ton) | Replacement |

| TS950-58ZB01 | 950 | 58 | 4.5 | KLK 950N |

| TS850-52ZB01 | 850 | 52 | 3.5 | KLK 850N |

| TS750-52ZB01 | 750 | 52 | 3 | KLK 750N |

| TS500-52ZB01 | 500 | 52 | 2 | KLK 500N |

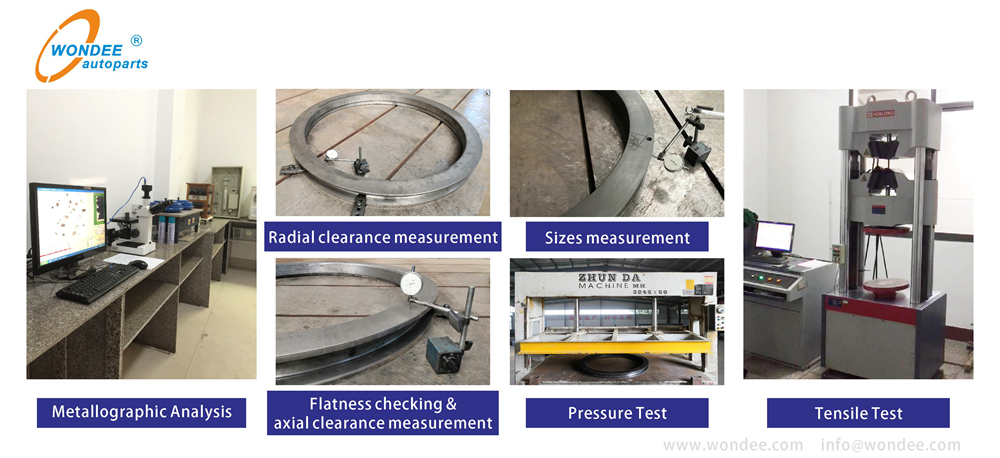

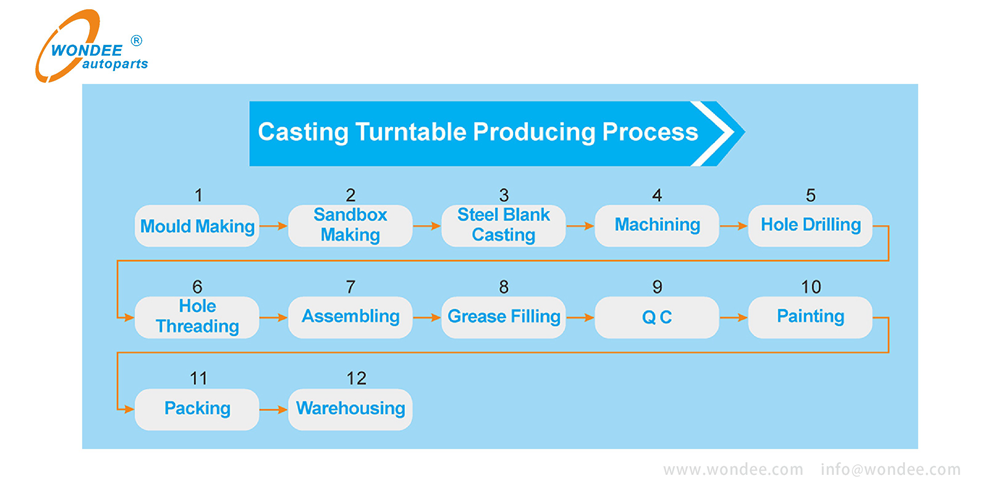

Manufacturing and Quality Control

Our factory occupies over 25,000 square meters and is equipped with more than 50 sets of machinery. We employ over 70 people, including 6 engineers. Our production process is meticulously managed, from mould making to final warehousing. Quality control includes metallographic analysis, radial and axial clearance measurements, and pressure and tensile tests.

The production process follows these steps: Mould Making → Sandbox Making → Steel Blank Casting → Machining → Hole Drilling → Hole Threading → Assembling → Grease Filling → Finished Product QC → Painting → Packing → Warehousing.

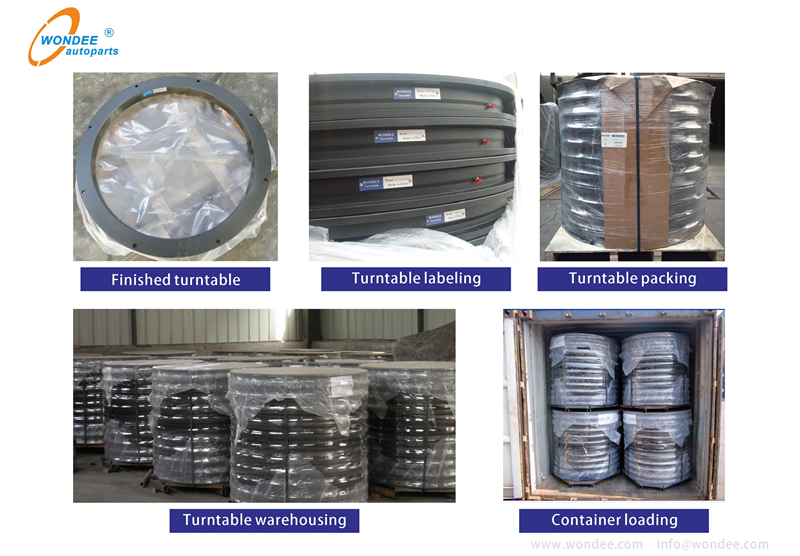

Packing and Logistics

We ensure proper packing, warehousing, and container loading for our trailer turntables.

Reviews

There are no reviews yet.