WONDEE Flatbed Semi Trailers for Cargo Transportation

- 20+ years of experiences (Since 1999)

- Production implementing ISO 9001-2015

- Services implementing ISO 9001-2015

- Technical standards: GB/T23336-2009, GB12676, GB1589-2016.

- 80%+ self-produced parts

- 100% quality inspection before shipment

- Warranty of chassis: 24 months since shipping date

- Sales volume (units): 10,000+ per year

- Number of R&D Staff: 11

- Customer satisfaction: 100% (OEM, ODM service Ok)

- Dispatch within Customized Production Based on Your Requirements : Your order will be manufactured according to your specifications (size, material, usage, etc.) with professional engineering support..

- Lead Time: 3–60 Days Depending on Quantity and Specification Warranty: Production and delivery time may vary based on your order volume and customization details. Contact us for an accurate schedule.

Description

Applications

A semi-trailer has axles placed behind the center of gravity and uses a king pin to transfer forces to the tractor. The tractor bears part of the trailer’s total load. Semi-trailers carry containers, bulk cargo, or special cargo, and are essential for global transportation.

Types include skeletal trailers, flatbed trailers, lowbed trailers, fence trailers, van trailers, oil tank trailers, bulk cement trailers, dump trailers, and car transport trailers.

Key Features

| Feature | Specification |

|---|---|

| Quality Management (Production) | ISO9001-2015 implemented |

| Quality Management (Services) | ISO9001-2015 implemented |

| Technical Standard | GB/T23336-2009, GB12676, GB1589-2016 |

| Certification | CCC obtained |

| Chassis & Axle Warranty | 24 months from shipping date |

| Material | From top 5 steel mills in China |

| Self-produced Parts | 80%+ |

| Interchangeable Parts | BPW, FUWA, JOST, YORK, WABCO, SAF |

| Cutting | CNC plasma and laser machines |

| Welding | Automatic gantry and robotic welding |

| Suspensions & Axles | WONDEE or client-specified brands |

| Landing Gear & King Pins | WONDEE or client-specified brands |

| Pneumatic System | China’s well-known brands |

| Wheels | China’s well-known brands |

| Shot Blasting | Large vehicle-body machines |

| Painting | Automatic dual-process lines |

| Inspection Before Shipment | 100% |

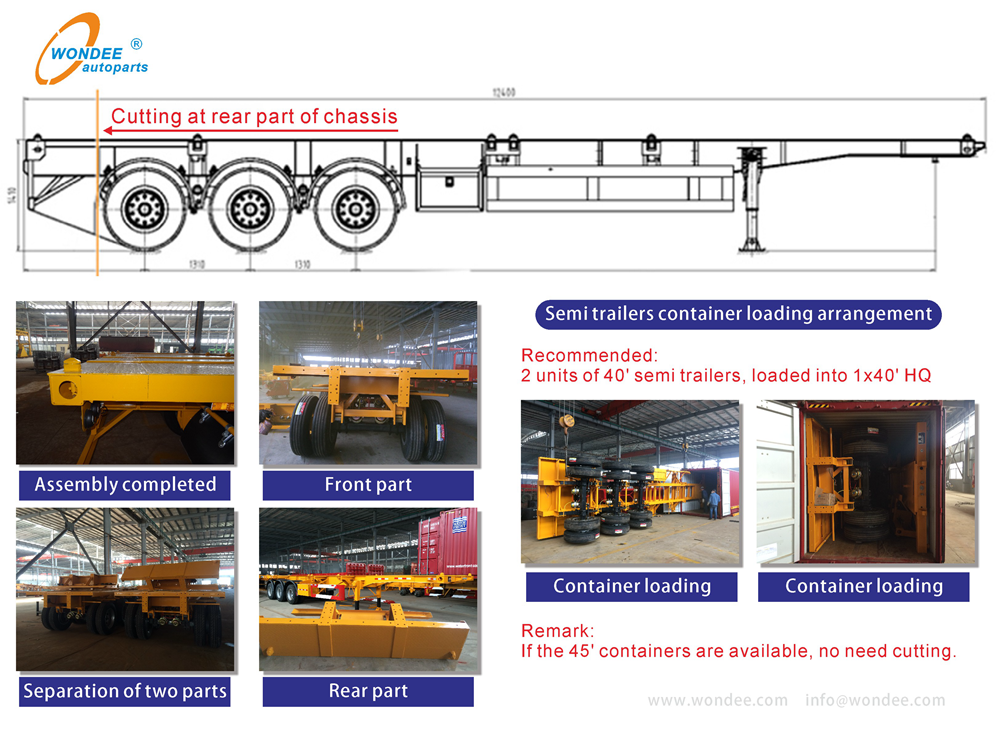

| Packing & Delivery | CKD/SKD, 40/45HQ container, RO-RO, Bulk cargo |

| Load Capacity | Exceeding Chinese standards |

| Annual Output | 10,000+ units |

| Overseas Market | 20+ countries including Philippines, Vietnam, Malaysia, Australia, and Africa |

| Clients | 30+ |

| Land Area | 60,000+ m² |

| Equipment | 200+ sets |

| Employees | 100+ |

| Engineers | 20 |

| Certificates | COC, PVOC, CIQ, SONCAP, C/O, FORM E, FORM A |

Specifications & Models

| MODEL | L*W*H (mm) | AXLE SPACE (mm) | TARE WEIGHT (kg) | PAYLOAD (kg) | RECOMMENDED TIRES |

|---|---|---|---|---|---|

| WFB2-4001 | 12410*2480*1520 | 8200+1310 | 6500 | 33600 | 11R22.5; 12R22.5; 11.00R20; 12.00R20 |

| WFB2-4002 | 12410*2480*1520 | 7160+1310 | 7500 | 38800 | 11R22.5; 12R22.5; 11.00R20; 12.00R20 |

| WFB3-4001 | 13000*2500*1500 | 6690+1310+1310 | 7000 | 33000 | 11R22.5; 12R22.5; 11.00R20; 12.00R20 |

Applications & Features

Semi-trailers carry containers, bulk cargo, oil, gas, food, wood, and other special loads. Customers select axle numbers, load capacity, and suspension types. Axle options include 2-axle, 3-axle, and 4-axle configurations. Suspensions can be air, bogie, or German/American types. Colors include red, yellow, orange, green, and blue. Payment terms: TT, LC, DP. Lead time: 15–20 working days. Minimum order quantity: 1 unit.

Production

Workshops of WONDEE Autoparts semi trailers:

(Plasma CNC cutting workshop, Main beams welding workshop, Chassis and suspensions welding workshop, Painting line, Final semi trailers wareshouing)

Factory facts of WONDEE Autoparts semi trailers:

| Land area (square meters ) | 60,000+ |

| Number of equipments (sets) | 200+ |

| Number of employees | 100+ |

| Number of engineers | 20 |

Production Lines & Equipment

WONDEE Autoparts uses advanced production lines for semi trailers, including:

- Plasma CNC cutting line

- Main beam welding line

- Chassis welding line

- Suspension turnover welding equipment

- Chassis shot peening line

- Chassis painting line

- Components assembling line

Semi-Finished Products

(Semi-finished components ready for assembly)

Product Details

(Detailed views of chassis, beams, and assembly points)

Final Products

Container Loading Arrangement

Production Range

(Flatbed, Fence/sidewall, Lowbed, Rear tipper, Dump, Stake, Oil tank, Bulk cement, Car transport trailers)

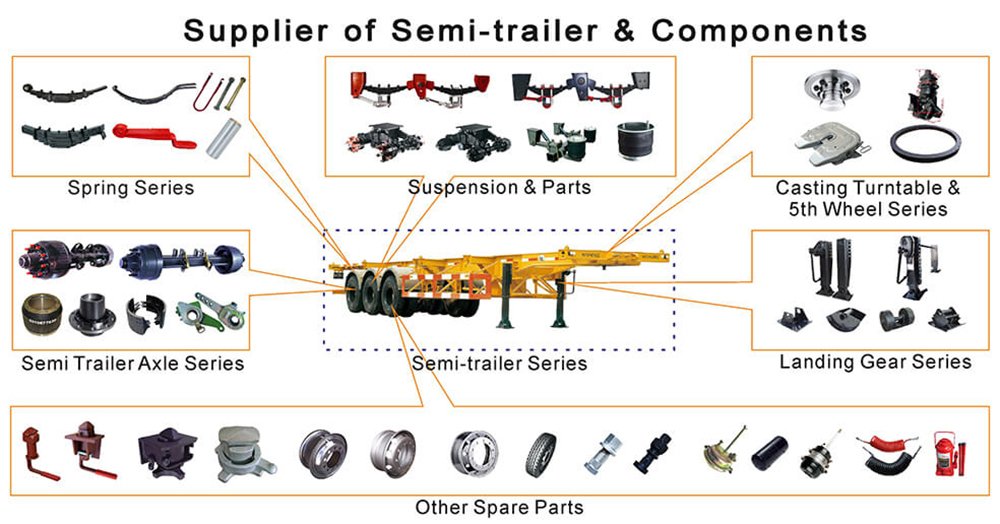

Main Components

Main semi-trailer components include:

- Beam and chassis

- Suspension system

- Semi trailer axles

- Landing gears

- Wheel and tires

- Twist locks

- Air tanks and air chambers

- King pins

- Pneumatic system

- Brake system

Full Range of Components

WONDEE Autoparts supplies both complete semi trailers and all essential components for custom assembly and maintenance.

Reviews

There are no reviews yet.