Description

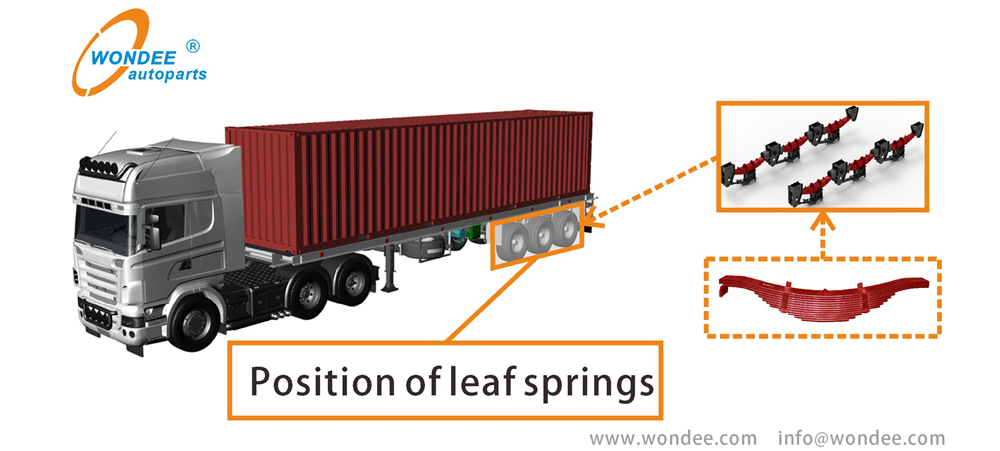

Leaf springs stand as the most widely used elastic elements in automobile suspensions today. They consist of several alloy spring sheets with equal width but unequal length, forming an approximate equal-strength steel beam. This design lets them transmit all forces and moments between wheels and frames, ease impact loads from the road, enable vehicle guidance, and keep vehicles running normally. You can find them in suspensions for heavy duty trucks, light duty trucks, pick-ups, cars, and various trailers like skeletal, lowbed, flatbed, and oil tank trailers, as well as agricultural vehicles.

WONDEE offers a diverse range of leaf springs to meet different application needs. Here are the main categories:

- Conventional leaf springs

- Parabolic leaf springs

- Z type air linkers

- TRA leaf springs

- Trailer leaf springs (including light duty trailer springs and boat trailer springs)

- Pickup leaf springs

- Semi trailer springs

- Truck springs (including heavy truck springs)

- Farming/agricultural trailer springs

- Sprung drawbar

- Bus springs

- Bogie/boogie springs

WONDEE leaf springs adhere to strict standards and use advanced processes to ensure performance and durability. Below is a detailed breakdown of their key features:

WONDEE leaf springs cover a wide range of parameters to fit various vehicle models and needs:

WONDEE provides a wide range of OEM leaf spring models specifically designed for USA trucks and suspensions. These models fit brands like FORD, FREIGHTLINER, FRUEHAUF, HUTCHENS, INTERNATIONAL, MACK, NAVISTAR, REYCO. Below is a selection of key OEM numbers:

The TRA series is a key line of leaf springs from WONDEE, including both parabolic and conventional types. Below are detailed specs for selected TRA models:

- WONDEE offers other unlisted TRA leaf springs to cover more specific application needs.

- Beyond the TRA series, WONDEE also provides all other leaf spring classifications mentioned earlier, ensuring full compatibility with different vehicle types.

Reviews

There are no reviews yet.