CATEGORIES

BRAKE DRUM

Your Position:Home>>Brake Drum

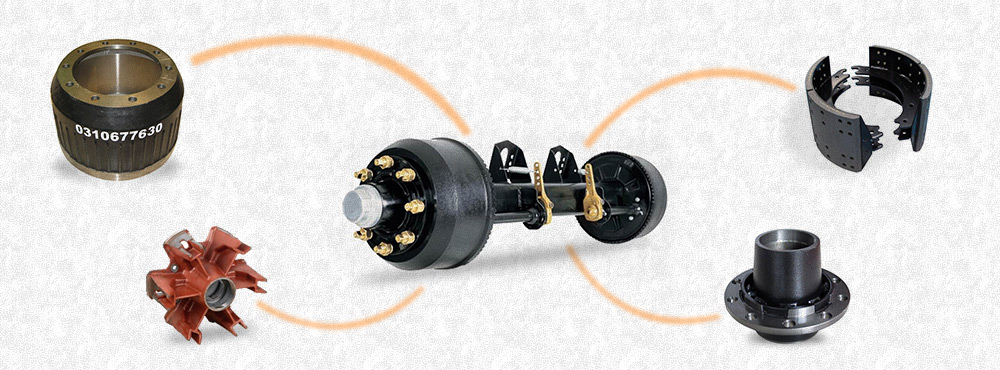

Drum Brake Components

2016-02-19 14:06:48

Drum brake components include the backing plate, brake drum, shoe, wheel cylinder, and various springs and pins.

Backing plate

The backing plate provides a base for the other components. It attaches to the axle sleeve and provides a non-rotating rigid mounting surface for the wheel cylinder, brake shoes, and assorted hardware. Since all braking operations exert pressure on the backing plate, it must be strong and wear-resistant. Levers for emergency orparking brakes, and automatic brake-shoe adjuster were also added in recent years.

Brake drum

The brake drum is generally made of a special type of cast iron that is heat-conductive and wear-resistant. It rotates with the wheel and axle. When a driver applies the brakes, the lining pushes radially against the inner surface of the drum, and the ensuing friction slows or stops rotation of the wheel and axle, and thus the vehicle. This friction generates substantial heat.

Wheel cylinder

One wheel cylinder operates the brake on each wheel. Two pistons operate the shoes, one at each end of the wheel cylinder. The leading shoe (closest to the front of the vehicle) is known as the primary shoe. The trailing shoe is known as the secondary shoe. Hydraulic pressure from the master cylinder acts on the piston cup, pushing the pistons toward the shoes, forcing them against the drum. When the driver releases the brakes, the brake shoe springs restore the shoes to their original (disengaged) position. The parts of the wheel cylinder are shown to the right.

Brake shoes are typically made of two pieces of steel welded together. The friction material is either riveted to the lining table or attached with adhesive. The crescent-shaped piece is called the Web and contains holes and slots in different shapes for return springs, hold-down hardware, parking brake linkage and self-adjusting components. All the application force of the wheel cylinder is applied through the web to the lining table and brake lining. The edge of the lining table generally has three “V"-shaped notches or tabs on each side called nibs. The nibs rest against the support pads of the backing plate to which the shoes are installed. Each brake assembly has two shoes, a primary and secondary. The primary shoe is located toward the front of the vehicle and has the lining positioned differently from the secondary shoe. Quite often, the two shoes are interchangeable, so close inspection for any variation is important.

Brake shoe assembly

Linings must be resistant to heat and wear and have a high friction coefficient unaffected by fluctuations in temperature and humidity. Materials that make up the brake shoe include, friction modifiers (which can includegraphite and cashew nut shells), powdered metal such as lead, zinc, brass, aluminium and other metals that resist heat fade, binders, curing agents and fillers such as rubber chips to reduce brake noise.

In the UK two common grades of brake shoe material used to be available. DON 202 was a high friction material that did not require a brake power servo. The disadvantage was that the lining was prone to fading on steep hills (calculate the kilowatts dissipated by a one-ton car descending a 15% hill at a constant 60 mph) A harder lining, the famous VG95 was produced but this required a brake servo. The other snag was that the parking brake would often fail the annual MOT test unless the high friction linings were installed just for the test.

Related Reading:Wheel Rim Trailer Axle

Tags: trailer brake drum brake shoe brake drum blog

Previous:The Advantage of Brake Drum